Contact Us

- Talk To Expert : +91 9527977770

-

Call

-

-

Address

B-68, Supa MIDC, Ahmednagar - Pune Road,

Dist - Ahmednagar, MH. 414301.

PEB Manufacturing

PRE-ENGINEERED BUILDINGS

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures.

We specialize in manufacturing and commissioning pre-engineered buildings (PEB) made in steel. Since the structure is built to order, it can be of any size and fulfil a wide range of structural and aesthetic design requirements. There are several advantages of PEBs over RCC structures and conventionally made steel buildings.

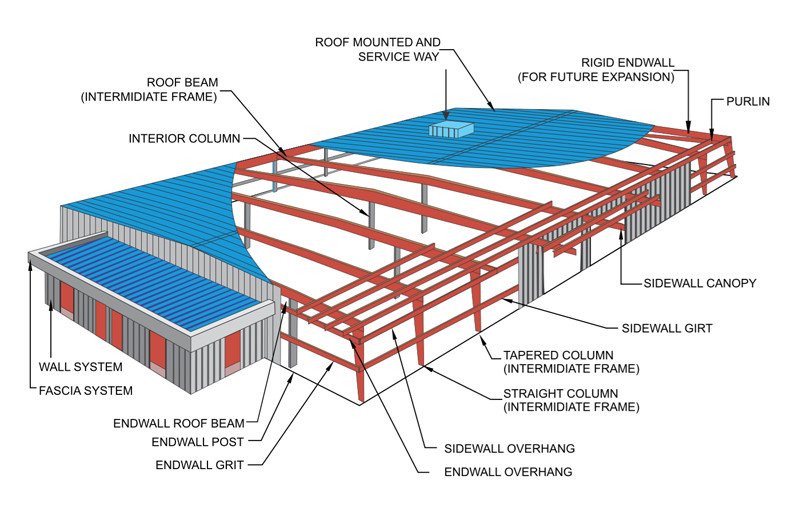

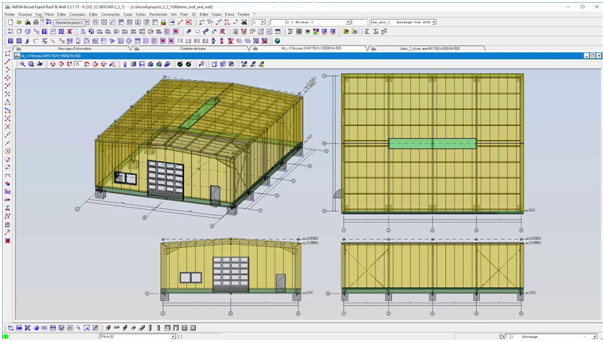

PEB 3D VIEW

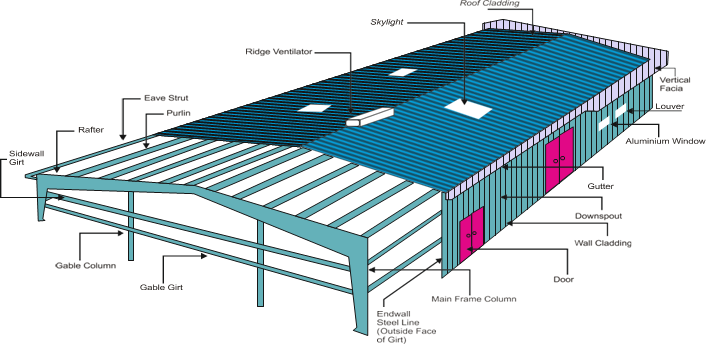

DESIGN & FABRICATION

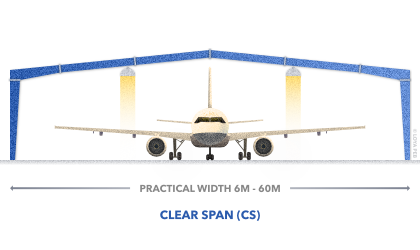

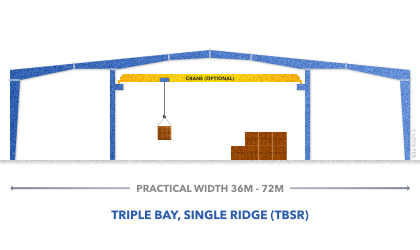

TYPICAL PEB FRAME TYPES

Clear Span

This frame type is suitable when unobstructed space is required. E.g. Aeroplane Hangars

Double Bay, Single Ridge

This is the most common frame type. It allows for greater widths without having too many interior columns.

Triple Bay, Single Ridge

Cranes can be added to any frame type. They are helpful in moving heavy objects in factories & warehouses.

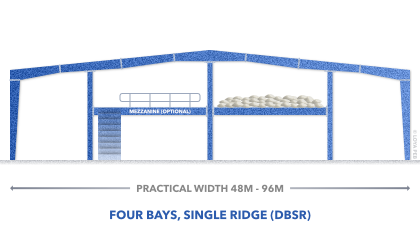

Four Bays, Single Ridge

Mezzanine structures add space to a structure. This additional space can be used for storage, office area, etc.

Single Slope

Monoslope structures are mainly used for smaller spans such as in parking sheds

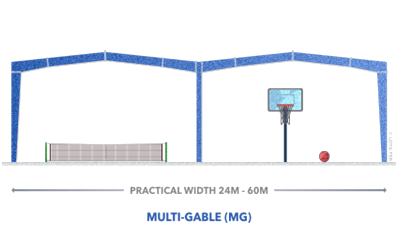

Multi-Gable

This structure type can provide wider spans without increasing the height by a large amount.

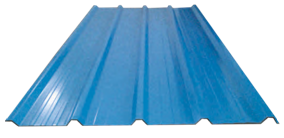

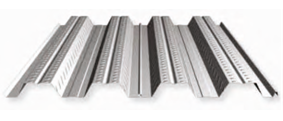

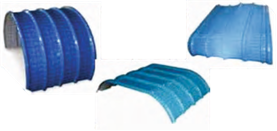

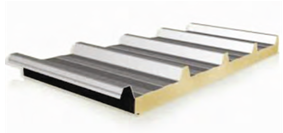

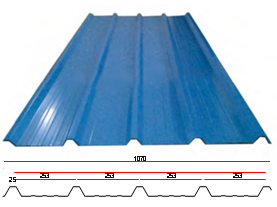

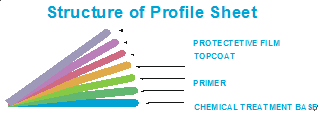

PROFILE SHEET

Triumph Technocrat profile sheet is made from the finest quality cold rolled steel coils which are coated with protected metallic and reinforced with multiple layers of organic coatings.

Triumph Technocrat profile sheet can be readily roll-formed, bent, pressed, cut, drilled, lock-seamed and stamped to suit the specific requirement without degradation in the quality of the paint.

Application: Industrial Roofing, Cladding, Farm House, Ware House, Etc.

Advantages: Weather proof & light weight, Maintenance free.

PRODUCTION FACILITIES

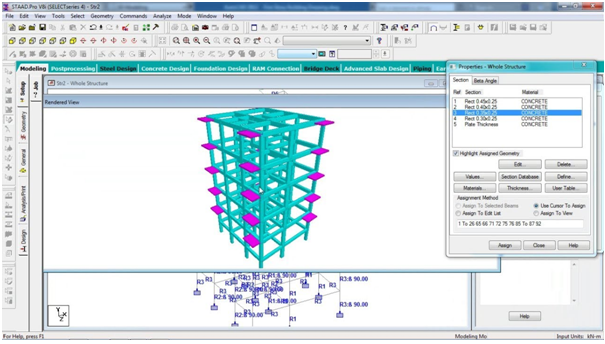

Manufacturing of pre-engineered buildings requires creative approach and high precision. Our design and engineering team uses latest software for all PEB designs. We use Autodesk AutoCAD, STAAD Pro, BO-CAD, Tekla X-Steel. Our team is trained to handle these complex software which enables them to design customized building structures. We arrange regular training session for our team to keep them updated with latest software version. We make necessary efforts to identify and arrange experts from necessary fields to train our teaMH.

This stage consists of a compute structural analysis to provide all the calculations that satisfy code requirement.

This stage consists of a compute structural analysis to provide all the calculations that satisfy code requirement.

The pre-fabricated structures or space frames are assembled on the ground and installed using crane or scaffolding. The structure will undergo full and complete final inspection after installation.

All structures are designed and manufactured strictly according to ISI specifications ensuring maximum safety and economy by making optimum use of quality raw materials and sheets. There is laboratory to check the raw materials to verify the standard of material supplied to us as well as to ascertain the quality of manufactured steel structures at various stages. The lab is equipped with all necessary equipment’s.

We ensure that we keep our commitments. Every project is completed as per customers’ timelines. We are proud to state that till date we have zero complaints w.r.t timelines. Our commitment and integrity has kept our customers satisfied and enabled to added new customers.

PRODUCTION FACILITIES

Design

Our experienced engineers work closely to design pre - fabricated structure, space frames as per owner's requirement & site conditions.

Engineering

This stage consists of a compute structural analysis to provide all the calculations that satisfy code requirement.

Manufacturing

Shop drawings are sent to the factory for fabrication; manufacture all structural members and accessories for complete installation.

Erection

The pre-fabricated structures or space frames are assembled on the ground and installed using crane or scaffolding. The structure will undergo full and complete final inspection after installation.

Quality Control SysteMH

All structures are designed and manufactured strictly according to ISI specifications ensuring maximum safety and economy by making optimum use of quality raw materials and sheets. There is laboratory to check the raw materials to verify the standard of material supplied to us as well as to ascertain the quality of manufactured steel structures at various stages. The lab is equipped with all necessary equipment’s.