-

Call

-

-

Address

B-68, Supa MIDC, Ahmednagar - Pune Road,

Dist - Ahmednagar, MH. 414301.

Cold Storage

Continuous Line Production Process

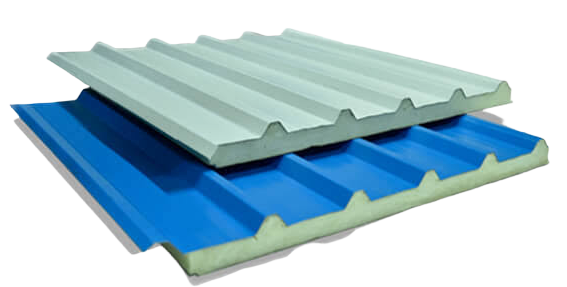

As the name suggests the Continuous Line Panel Production process involves all operations starting from forming sheet metal profiles required for faces, panel to panel joining profile detail, Foaming, Panel Forming, Curing and final cutting of product to length in one continuous process.

At the start of the production process two number de coilers are loaded with Steel Coils of the required colour and thickness. These Steel coils are then fed into two separate Roll formers for the forming of the sheet metal profiles and the panel joining profile. After the roll forming the two steel facings pass through the heating chambers and then move to the moulding area. Next the Urethane Chemicals in liquid form are sprayed on to the lower steel sheet. Where needed, the inner surface of steel sheet is given a ‘CORONA’ treatment to improve the bonding strength. The chemical system is delivered in to the cavity by an oscillating manifold on which delivery nozzles are mounted at equal spacing. The chemical system starts reacting after the ‘cream time’ is reached. The foam then starts to rise, till the ‘rise time’ is completed. The top surface of the foam starts to adhere to the bottom surface of the top sheet after the ‘tack-free’ time is attained. All these reactions proceed even as the whole ‘mould’ is moving along.

The Pressure platen conveyors over the two sheets along with the side belts are long enough to keep the “Sandwich“ in closed state for a sufficiently long duration so that the finished panel is fully cured in all respects before it emerges from the double belt area of the line. After this the panel is cut to the required size on the band saw cutting machine.

Discontinuous Type Production Process.

As the name suggests in this production process the panel is manufactured by different processes being carried out on different machines to get the final product.

The major equipment used for this process is the Foaming Machine and the Panel Press which features a vertical hydraulic ram of the length and width of the panel to be manufactured.

Profiling of the Metallic/FRP/Cement Board facing is done as an ‘off line’ processes and brought to and stacked on either end of the panel press. Then the mould is created as follows:

The base on which the bottom facing is placed is a precisely machined flat Platen equipped with a built in heating system. Sides of the mould are made of machined Aluminium extrusions (jigs), profiled to the male and female joint features desired. These jigs are specific to each thickness of panel being produced. Jigs also feature accurately positioned fixtures to mount Camlocks which get embedded in to the foam later. When the pre-profiled top and bottom facing sheets are placed in this mould with special spacers, a hollow space is created and is now ready for chemical injection. This complete pre-assembly is moved laterally into the press by a positioning actuator. A heavy ram, which is a precision machined guided block, closes the mould tightly and holds the ‘mould’ firmly. The temperature controlled heated platens keep the mould at the optimum reaction temperature. Through many nozzles provided on the sides of the ‘mould’, PU chemicals mix is injected to precise volume as per settings in the microprocessor controlled delivery head. The liquid mix finds its level well before the ‘cream time’ of the chemicals is reached. The foaming reaction starts and the foam rise gradually to fill the nooks and corners of the mould. The rising of the foam is complete well before the ‘tack-free’ time, when the adhesion to the sheets starts- i.e., well after the foam has filled the ‘mould’. The assembly is held in position; in the preheated mould till after the mould release time has elapsed. Then the panel is ejected out of the press.